Need help with EMC testing? Schedule a free consultation with our team to discuss EMC testing and achieving compliance for your product, or call us on 866-540-5287 to talk to our compliance experts right away.

Get Free Help for Your EMC Testing & Compliance Questions

Need help carrying out EMC testing and complying with regulations?

Enter your name, email address and question, and our engineering team will contact you with the information you need to solve your EMC testing questions and achieve compliance for your product.

If you aim to manufacture or sell an electronic device in the United States, your product needs to undergo testing to ensure optimal electromagnetic compatibility. The testing process is very extensive to confirm that your device fulfills the FCC’s requirements. Once your product passes testing, you will receive the FCC’s official seal of approval, which grants you permission to put the product on sale.

To ensure that you understand each step of the process, it’s important to familiarize yourself with the inner workings of electromagnetic compatibility (EMC). Here is an overview of how EMC is measured and how you can ensure that your electronic device passes the test.

What Is EMC Testing?

EMC testing is a mandatory step toward obtaining FCC approval for your electronic product. There are two main types of EMC testing: emissions testing and immunity testing.

Emissions testing seeks to verify that your product’s emissions do not exceed the limits for that specific product category. According to emissions testing guidelines, a user should be able to operate your product under normal conditions without being exposed to harmful interference.

Immunity testing helps to ensure that the electronic device in question meets standard expectations. When used in its normal operating environment, the device should operate as expected and without any problems. In addition, immunity testing measures how your device responds to certain stimuli, such as electromagnetic noise that is emitted from other types of equipment.

How EMC Is Measured

To confirm that your electronic product passes both emissions testing and immunity testing, it must undergo a formal EMC measurement process. Understanding how EMC is measured can help better prepare you for testing.

The main purpose of EMC testing is to target radiated emissions. Radiated emissions are disturbances that are unintentionally generated by an electronic device. These emissions are diffused through the air and typically originate from interconnected cables.

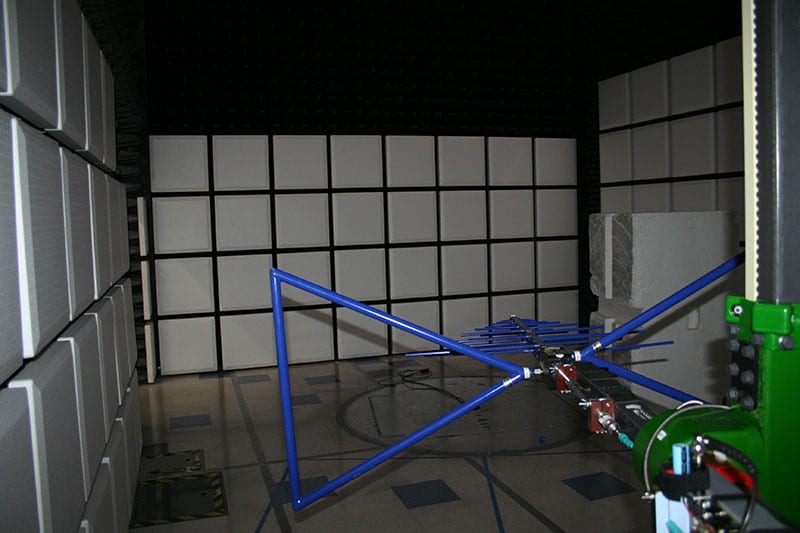

During the testing process, a spectrum analyzer is used to produce radiated emissions measurements. Some testing officials may also make use of a measuring antenna to facilitate the process. The purpose of these tools is to measure the strength, size and compliance of radiated emissions in the most accurate way possible.

EMC testing also tackles conducted emissions. Conducted emissions refer to the amount of electromagnetic energy that is conducted into a power supply cord. During EMC testing, these emissions are carefully measured to ensure that they don’t exceed the specified limits.

The purpose of conducted emissions testing is to identify and isolate any radiofrequency signals that shouldn’t be present. To increase your chances of passing this portion of the testing process, it’s crucial to ensure that you have a thorough understanding of the process and that you’re prepared to submit your electronic device for testing.

Successfully Navigating the EMC Testing Process

Going through EMC testing may seem daunting, but enlisting the help of a professional can reduce stress and uncertainty while boosting your chances of success. The highly skilled experts at Compliance Testing are equipped to help you successfully navigate the EMC testing process.

No matter what type of electronic device you want to sell or manufacture, we can bring you closer to securing official FCC approval with help from our state-of-the-art testing equipment and unparalleled experience in the field. Contact us today to learn about how we can help.